Mk.4 (1962 – 1965)

Bolwell Cars’ first production vehicle was cleverly named the Mk.4. Campbell Bolwell’s reasoning was that no-one, not even an enthusiast, would want to buy the first “guinea pig” model from any manufacturer. So Mk.4 it was. Colin Chapman, one of Campbell’s heroes, had done a similar thing when naming his production cars. In retrospect, given that there were actually four pre-production Bolwell specials, perhaps it should more accurately have been called the Mk.5.

Bolwell Cars’ original advertisement in Sports Car World led with the headline “be the fastest man…” and then in smaller type “on the road using a superbly built Bolwell body-chassis unit”. Later advertising specifically identified the car as a Bolwell Mk.4, and described it as “a lightweight sports racing car designed and constructed to cover a wide variety of needs. Whether you want a car for racing or for your own pleasure on the road – this is the car for you”.

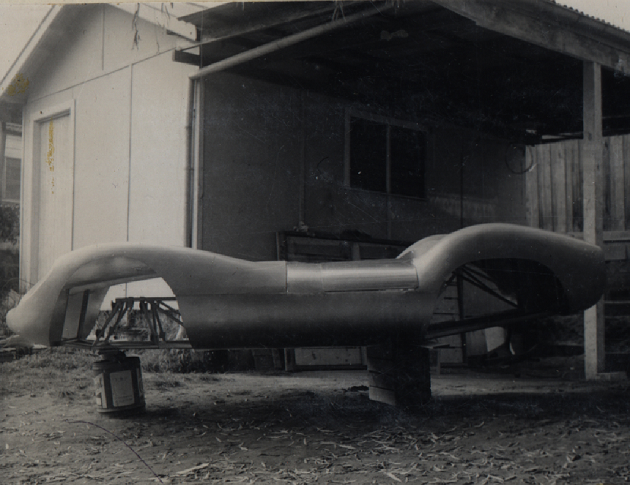

The Bolwell Mk.4 was clearly aimed at motoring enthusiasts with little money but with some mechanical knowledge and unbridled enthusiasm. Design influences for the Mk.4 included the Elfin Streamliner, the Lotus 11, and the Maserati Birdcage, the latter so named because of its intricate tubular spaceframe chassis. The Bolwell spaceframe was unusual because traditionally there were three chassis compartments; the engine; the cockpit to the scuttle; and the cockpit to the back; and the suspension was hung off the back and the front. Bolwell only used two compartments, with the driver’s feet pushed through the main bulkhead and the engine moved right back to the offside of the driver’s legs to get better weight distribution, more like a rear engined car.

The Bolwell chassis was light, only about 50 pounds or so, and comprised of 1”, ¾” and 5/8” round and section mild steel tubing. The frames were built in a jig for accuracy and consistency, and finished in a hammertex grey coating. Body weight was minimized by the use of full aluminium floor panels, inner guards, and cockpit sides and hinged dropdown doors. Fibreglass was used for the front and rear sections, which were hinged at the front and rear of the frame to allow maximum accessibility. Overall weight for the body-chassis unit was claimed to be “a mere 1½ cwt” with potential for a fully assembled car to weigh in at around 8½ cwt.

The chassis was designed to accommodate a range of stock component parts including:

- Triumph Herald front suspension (ie wishbones, anti-sway bar, brakes and wheels) which was quite popular in those days with Lotus and others. It had very good geometry and rack and pinion steering.

- Standard 10 brake and clutch hydraulic pedal unit, radiator and differential complete with rear brakes, used in conjunction with an A frame and two trailing links.

- Morris Minor petrol tank

- Fiat 1100 battery

- Ford “Kent” 4 cylinder engine and gearbox units. Taller engines such as BMC, Peugeot, Simca, Hillman etc could be used with a bonnet bulge.

Constructing the fibreglass body was a new challenge for Campbell Bolwell. He had previously learnt some metal working skills with his earlier specials and was quite comfortable working with metal, but fibreglass was still a new medium, and new techniques had to be tested, and refined. Much of the effort, locked away in the family garage, was simply trial and error, building a set of plaster moulds for the front and rear sections of the car. Campbell did have the nous to keep the design of the fibreglass panels reasonably straightforward so the moulds weren’t overly complex.

As such, the Bolwell Mk.4 was designed entirely consistent with Campbell Bolwell’s ideas in relation to low height and good aerodynamics, minimal weight, and balanced front-rear weight distribution.

In addition to the more usual sports body-chassis unit, Bolwell also offered a GT body-chassis unit, which basically shared the same chassis as the sports model, but came with an entirely different rear fibreglass section which included an “armourfloat” windscreen and a large perspex rear window. The GT had hinged gull-wing type doors with fixed side windows. Manufacture of the doors was quite primitive, with the doors being cut out of the body/roof panel with a jig saw, and aluminium frames affixed to provide some strengthening.

At ₤169 for the Mk.4 body/chassis unit, sales were quite brisk, but after a year or so, Campbell commenced a review of the business. One outcome of that review was that the price was increased to ₤198, and ₤298 for the GT version. Another outcome was the introduction of a new lower cost, more labour efficient, unitary back-bone type chassis and a new version of the Mk.4.

The new version became known as the Bolwell Mk.4B. As well as changes to the chassis, the body work was slightly redesigned and some of the ‘swoopiness’ removed – many enthusiasts prefer the Mk.4B’s more refined lines. The interior was also redesigned. Advertisements claimed many other advantages with the unitary construction, including integrated footwells, transmission tunnel and fibreglass dash, increased cockpit room, higher torsional stiffness, and lower overall weight. By the time that production stopped in 1965, Bolwell Cars had sold approximately 80 Mk.4 body/chassis units, including 12 GT versions.

Bolwell Mk.4 – Dimensions and Specifications

(Sourced from Bolwell promotional material)

| DIMENSIONS: | |

| Wheelbase | 84” (2133 mm) |

| Track – Front | 50” (1270 mm) |

| Track – Rear | 49” (1244 mm) |

| Overall Length | 137” (3480 mm) |

| Overall Width | 60” (1524 mm) |

| Height at Scuttle | 24½” (622 mm) |

| Ground Clearance | 5” (127 mm) |

| Weight | Complete car between 950 lb (432 kg) and 1065 lb (485 kg) depending on engine fitted |

| SPECIFICATIONS: | |

| Chassis | 4A – fully stressed space frame 4B – spot-welded steel back-bone |

| Body | Combination of aluminium and fibreglass panels |

| COST: | |

| ₤198.00 | Sports Body/Chassis Unit |

| ₤298.00 | GT Body/Chassis Unit |

| Available extras | |

| ₤8.15 | Armstrong coil spring shock absorber (each) |

| ₤10.00 | Fixing of necessary brackets to rear axle to accommodate trailing arms, A bracket and suspension units |

| ₤10.00 | Set of 2 Trailing arms and A bracket for location of rear end |

| ₤25.00 | Set of lightweight wishbones |

| ₤6.10 | Aerodynamic bonnet bulge for larger motors |

| ₤6.10 | Full width roll bar for GT |

| ₤5.00 | Fibreglass bucket seats, blank form |

Bolwell Car Club of Australia

Bolwell Car Club of Australia